Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details4-axis CNC machines expand traditional machining by adding rotational movement for more complex parts and efficient workflows. From wood 4 axis CNC machines used in carving to milling machines 4 axis CNC for precision components, these systems reduce setups while improving accuracy.

Whether you’re upgrading from a 3-axis system or need rotational machining, a 4 axis CNC router or 4 axis CNC mill delivers versatility across materials. This collection includes robust 4 axis machines designed for production, prototyping, and detailed machining.

Save $0.00

Save $0.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-5,700.00

Save $-5,700.00

Shapeoko HDM CNC Router: Industrial-Grade Precision for Professionals and Makers Alike The Shapeoko HDM CNC Router represents the peak of precision...

View full details Save $0.00

Save $0.00

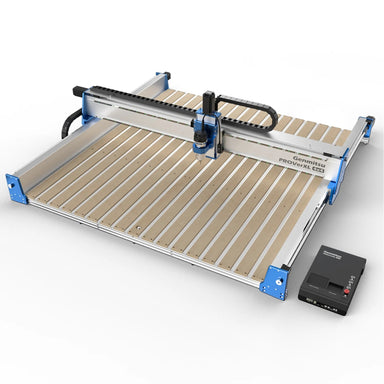

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-1,399.00

Save $-1,399.00

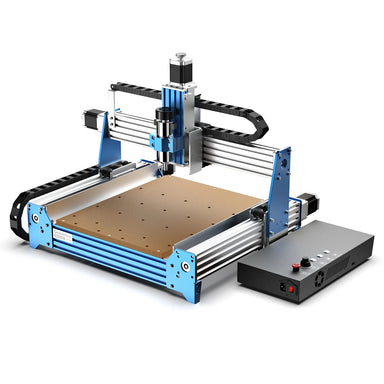

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $0.00

Save $0.00

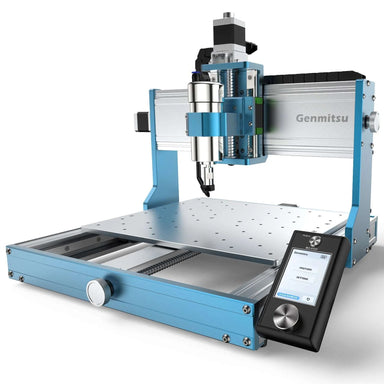

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-2,800.00

Save $-2,800.00

Nomad 3 Desktop CNC Mill: Professional-Grade Power in a Compact Package The Nomad 3 Desktop CNC Mill from Carbide 3D is the next evolution of prec...

View full details Save $-1,799.00

Save $-1,799.00

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-949.00

Save $-949.00

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full details

A 4-axis CNC machine is a system that adds a rotational axis to standard X, Y, and Z movement. This allows parts to be rotated during machining for more complex shapes and multi-side work.

4 axis means the machine can move along three linear axes plus one rotational axis, typically called the A axis. This rotation enables machining around cylindrical or multi-sided parts.

The key difference is rotational capability. A 3-axis machine cuts from one direction, while a 4-axis CNC machine rotates the material to machine multiple sides without repositioning.

A 4-axis CNC machine adds one rotational axis, while a 5-axis system adds two rotational axes. Five-axis machines handle more complex geometries, but 4-axis machines offer a strong balance of capability and cost.

The A and B axes are rotational axes. The A axis rotates around the X axis, while the B axis rotates around the Y axis, allowing angled and multi-directional machining.

A true 4th axis allows continuous rotation during cutting, while a fake or indexed 4th axis only rotates between operations. True 4-axis machining enables smoother, more complex parts.

4-axis machines can cut wood, plastics, foam, composites, and metals, depending on whether the system is a 4 axis CNC router, 4 axis milling machine, or 4 axis lathe CNC.

4-axis CNC machines are widely used in woodworking, furniture making, aerospace components, mold making, signage, and manufacturing.

For many users, a 4-axis machine is a significant upgrade in capability. It reduces setup time, improves accuracy, and enables designs not possible on 3-axis systems.

Shipping Insurance ($89)