Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full detailsIndustrial CNC machines are built for high-volume production, precision machining, and continuous operation in demanding environments. From large-format cutting to complex machining, an industrial cnc machine delivers speed, rigidity, and repeatable accuracy at scale.

Whether you’re running an industrial wood cnc machine for panel processing or an industrial metal cnc machine for precision parts, these systems are engineered for reliability and long-term performance. This collection features industrial CNC routers and machining solutions designed for professional manufacturing.

Save $0.00

Save $0.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-5,700.00

Save $-5,700.00

Shapeoko HDM CNC Router: Industrial-Grade Precision for Professionals and Makers Alike The Shapeoko HDM CNC Router represents the peak of precision...

View full details Save $0.00

Save $0.00

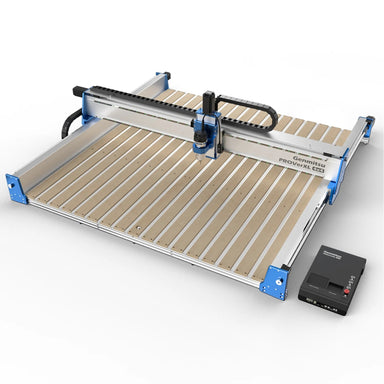

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-1,399.00

Save $-1,399.00

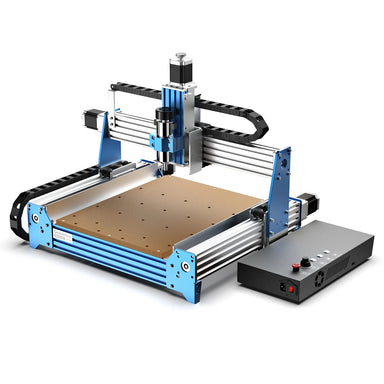

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $0.00

Save $0.00

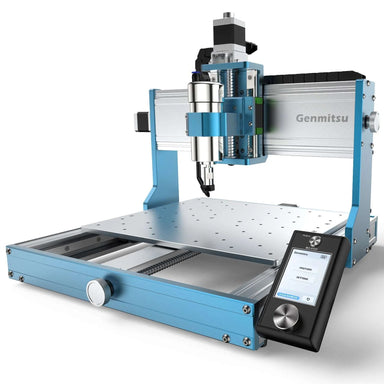

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-2,800.00

Save $-2,800.00

Nomad 3 Desktop CNC Mill: Professional-Grade Power in a Compact Package The Nomad 3 Desktop CNC Mill from Carbide 3D is the next evolution of prec...

View full details Save $-1,799.00

Save $-1,799.00

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-949.00

Save $-949.00

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full details

Industrial CNC machine pricing varies based on size, material capability, automation, and precision. Entry-level industrial systems cost less, while large-format or metal-focused machines represent a higher investment due to power and durability.

Yes, CNC machines can cut and shape complex 3D forms. Industrial CNC routers and mills are commonly used for 3D carving, contouring, and multi-axis machining in wood, metal, and composites.

CNC machines use CAD software for design and CAM software for toolpath generation. Industrial CNC workflows rely on robust software capable of handling complex geometries and production-scale jobs.

Industrial CNC machines can cut wood, MDF, plastics, composites, aluminum, steel, and other metals, depending on machine configuration and tooling.

Industrial CNC machines are built for continuous operation, higher accuracy, and heavier cutting loads. They feature stronger frames, more powerful spindles, and advanced control systems.

With proper maintenance, industrial CNC machines can last 15–25 years or more, even in demanding production environments.

No. While common in factories, industrial CNC routers are also used by cabinet shops, sign manufacturers, furniture makers, and fabrication businesses that require professional-grade output.

Many industrial CNC machines require three-phase power or higher electrical capacity, depending on spindle size and automation features.

Yes. Industrial CNC systems are designed for scalable production, allowing businesses to increase output without sacrificing consistency or quality.

Shipping Insurance ($89)