Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full detailsCNC machines for MDF are built to deliver clean, accurate cuts for furniture, cabinetry, and decorative woodworking. From a cnc router for mdf in a small shop to a production-grade mdf cnc cutting machine, these systems handle dense fiberboard with precision and consistency.

Whether you’re manufacturing panels, cabinetry components, or cnc machine for mdf doors, this collection features machines designed for smooth edges and repeatable results. Explore cnc router machines for mdf cutting that support high-volume output without sacrificing accuracy.

Save $0.00

Save $0.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-5,700.00

Save $-5,700.00

Shapeoko HDM CNC Router: Industrial-Grade Precision for Professionals and Makers Alike The Shapeoko HDM CNC Router represents the peak of precision...

View full details Save $0.00

Save $0.00

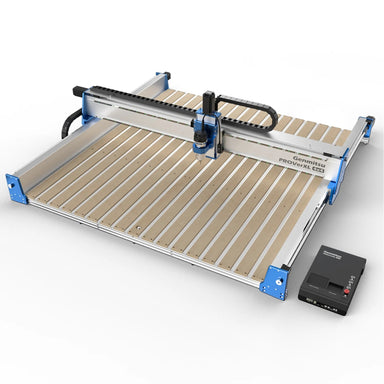

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-1,399.00

Save $-1,399.00

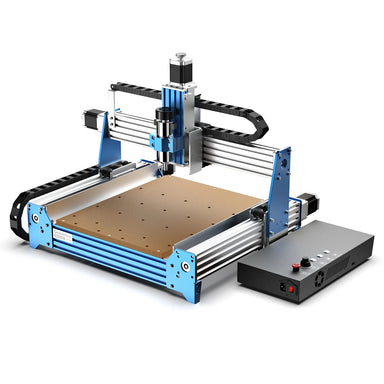

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $0.00

Save $0.00

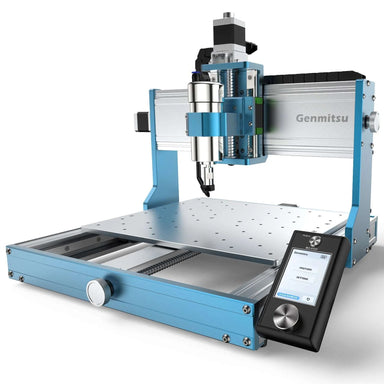

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-2,800.00

Save $-2,800.00

Nomad 3 Desktop CNC Mill: Professional-Grade Power in a Compact Package The Nomad 3 Desktop CNC Mill from Carbide 3D is the next evolution of prec...

View full details Save $-1,799.00

Save $-1,799.00

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-949.00

Save $-949.00

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full details

Yes, CNC machines are ideal for cutting MDF. A cnc cutting machine for mdf provides smooth, consistent cuts and is widely used for cabinetry, furniture parts, and decorative panels.

CNC settings for MDF depend on tooling, spindle speed, and feed rate, but MDF is typically cut at higher speeds with proper dust extraction. Correct settings reduce tear-out and extend tool life when using a cnc machine for mdf cutting.

MDF is easy to cut but abrasive. While it machines smoothly, it produces fine dust and can wear tools faster than solid wood. CNC routers for mdf are designed to handle this with rigid frames and efficient chip removal.

A well-maintained CNC machine can last 10–20 years or more. Machines built for MDF cutting with quality components, proper maintenance, and regular servicing offer long-term reliability in both small shops and production environments.

CNC machines for MDF are commonly used for cabinet doors, wall panels, furniture components, signage, moldings, and decorative routing.

Yes, MDF can wear cutting tools faster due to its resin and fiber content. Using carbide bits and maintaining proper cutting parameters helps extend tool life on cnc router machines for mdf.

Dust collection is critical when cutting MDF. MDF produces very fine dust, and effective extraction improves cut quality, machine longevity, and operator safety.

Absolutely. A cnc machine for mdf doors delivers high precision and repeatability, making it ideal for raised panels, routed designs, and consistent production runs.

Yes. MDF is forgiving to machine, and modern CNC routers offer user-friendly software and presets, making MDF an excellent material for learning CNC routing.

Shipping Insurance ($89)