Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full detailsOur CNC machines for stone carving, cutting, and engraving are engineered for makers, fabricators, and monument shops that demand uncompromising precision. From granite CNC machines to advanced 3D stone carving machines, these systems deliver clean cuts, sharp detail, and consistent results across marble, granite, slate, quartz, and more.

Whether you’re producing engraved memorials, architectural features, inlays, or artistic reliefs, a CNC router for stone gives you digital-level control over complex shapes and deep carving paths. These CNC machines for stone cutting and engraving transform raw stone into refined, high-value finished pieces with repeatable accuracy.

Save $0.00

Save $0.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-5,700.00

Save $-5,700.00

Shapeoko HDM CNC Router: Industrial-Grade Precision for Professionals and Makers Alike The Shapeoko HDM CNC Router represents the peak of precision...

View full details Save $0.00

Save $0.00

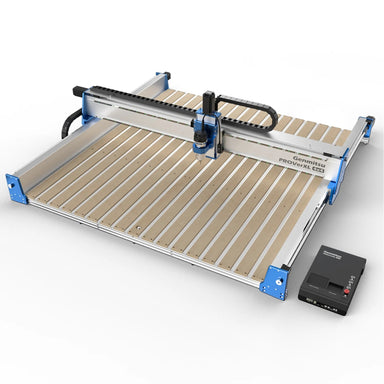

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-1,399.00

Save $-1,399.00

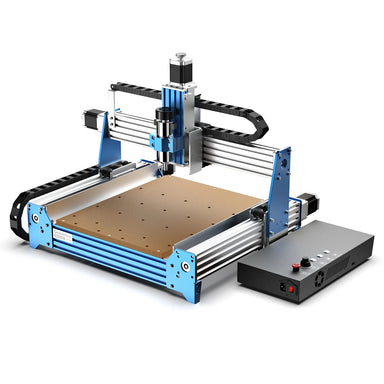

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $0.00

Save $0.00

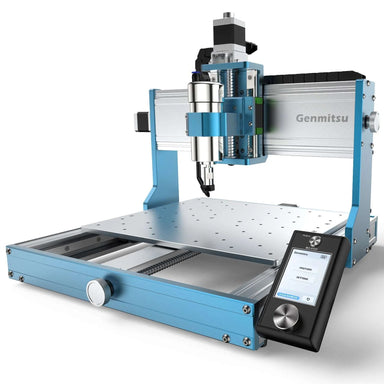

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-2,800.00

Save $-2,800.00

Nomad 3 Desktop CNC Mill: Professional-Grade Power in a Compact Package The Nomad 3 Desktop CNC Mill from Carbide 3D is the next evolution of prec...

View full details Save $-1,799.00

Save $-1,799.00

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-949.00

Save $-949.00

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full detailsYes — modern CNC machines are specifically designed to cut stone accurately and safely. With diamond tooling and rigid motion systems, a CNC machine for stone cutting can shape granite, marble, slate, quartz, and limestone while maintaining consistent depth and edge quality across long production runs.

Stone is cut using diamond-coated tools mounted on CNC routers or stone machining centers. These include diamond end mills, engraving bits, and core drills that are purpose-built to withstand stone’s hardness while delivering smooth finishes and controlled material removal.

Most professional stone CNC machines can cut 1–6 inches of stone depending on spindle power, tooling, and machine rigidity. Industrial granite CNC machines can exceed this range when performing deep pocketing, profiling, or multi-pass cutting operations.

A CNC router for stone is used for engraving text, carving relief artwork, cutting profiles, machining inlays, and producing architectural stone components with repeatable digital accuracy.

Yes — a CNC machine for stone engraving can etch fine lettering, logos, portraits, and ornamental patterns directly into granite, marble, slate, and other natural stones using diamond engraving tools.

A 3D stone carving machine is a specialized CNC platform designed for multi-axis relief carving, sculptural detailing, and dimensional surface machining, allowing complex textures and contours to be produced automatically from CAD models.

Yes — water cooling and dust suppression are essential when machining stone. Coolant systems extend tool life, reduce micro-fracturing, and keep airborne silica dust safely controlled.

Absolutely — granite CNC machines are built specifically to handle granite’s hardness and density, making them ideal for monuments, countertops, architectural features, and engraved stone signage.

Shipping Insurance ($89)