Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full detailsOur CNC machines for metal are engineered for makers, fabricators, and machine shops that require true rigidity, torque, and dimensional accuracy. From compact desktop CNC machines for metal to full-frame CNC milling machines for metal, these systems deliver clean cuts, tight tolerances, and consistent surface finishes across aluminum, brass, steel, and alloys.

Whether you’re producing prototypes, production parts, brackets, enclosures, or engraved components, a CNC router for metal gives you digitally controlled feeds, depths, and repeatable toolpaths. These CNC machines for metal cutting and fabrication transform raw stock into production-ready parts with confidence and speed.

Save $0.00

Save $0.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-5,700.00

Save $-5,700.00

Shapeoko HDM CNC Router: Industrial-Grade Precision for Professionals and Makers Alike The Shapeoko HDM CNC Router represents the peak of precision...

View full details Save $0.00

Save $0.00

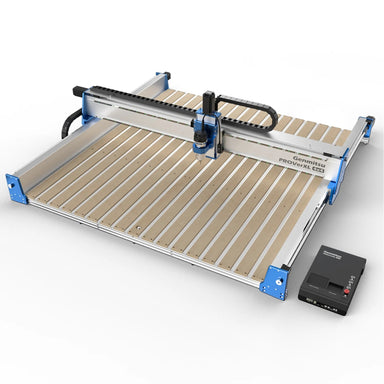

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-1,399.00

Save $-1,399.00

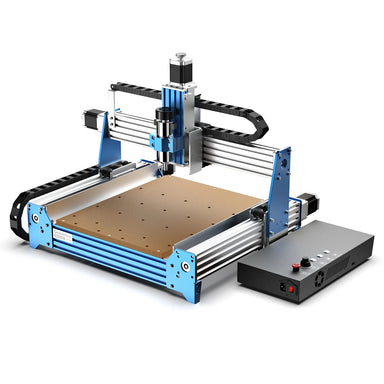

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $0.00

Save $0.00

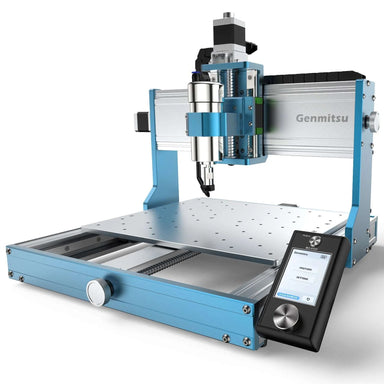

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-2,800.00

Save $-2,800.00

Nomad 3 Desktop CNC Mill: Professional-Grade Power in a Compact Package The Nomad 3 Desktop CNC Mill from Carbide 3D is the next evolution of prec...

View full details Save $-1,799.00

Save $-1,799.00

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-949.00

Save $-949.00

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full detailsNot at all — most beginners can start producing usable metal parts within days. Modern CNC software, preset cutting profiles, and guided toolpath generators make CNC metal machining far more approachable than traditional manual milling.

CNC machines can cut aluminum, brass, copper, mild steel, stainless steel, and many alloys when using proper tooling, spindle speeds, and coolant.

A CNC milling machine for metal offers higher rigidity, stronger spindles, and precision ball screws for deeper cuts and tighter tolerances, while routers are better suited for lighter metal cutting and engraving.

Yes — desktop CNC machines for metal are excellent for prototyping, education, small-batch production, and engraving, offering high accuracy in compact footprints.

Most small CNC machines for metal can cut ¼″–1″ thick metal, while industrial machines can exceed that depending on tooling, spindle power, and machining strategy.

Metal machining uses solid carbide end mills, coated drills, engraving bits, and coolant systems to ensure clean finishes and long tool life.

Yes — coolant improves surface finish, tool longevity, and dimensional accuracy by reducing heat and friction during cutting.

CNC metal fabrication is used to produce machine parts, brackets, enclosures, fixtures, jigs, and structural components with consistent precision and repeatability.

Shipping Insurance ($89)