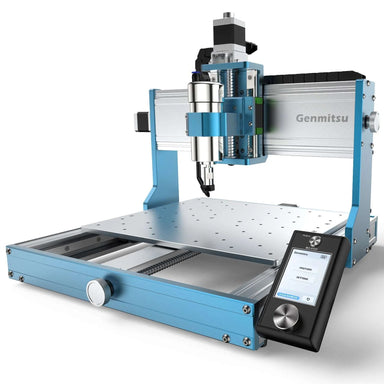

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full detailsCNC machines for wood give makers, shops, and manufacturers the power to cut, carve, engrave, and mill wood with exceptional accuracy. Whether you need a small cnc machine for wood in a home workshop or a large cnc machine for wood in a production environment, these systems deliver consistent results across hardwood, plywood, MDF, and more.

From cnc router machines for wood cutting to advanced cnc machines for wood carving and engraving, this collection includes solutions built for efficiency, repeatability, and creative freedom. Explore cnc routers for wood that support everything from custom furniture and cabinetry to signs, décor, and precision woodworking projects.

Save $0.00

Save $0.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-5,700.00

Save $-5,700.00

Shapeoko HDM CNC Router: Industrial-Grade Precision for Professionals and Makers Alike The Shapeoko HDM CNC Router represents the peak of precision...

View full details Save $0.00

Save $0.00

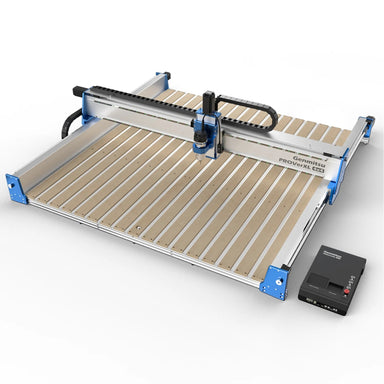

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-1,399.00

Save $-1,399.00

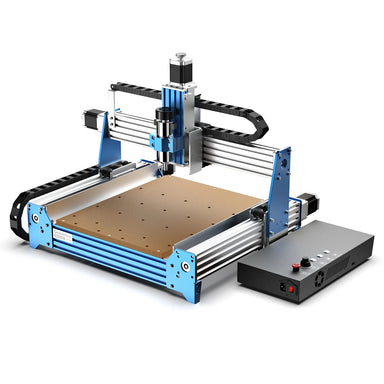

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $0.00

Save $0.00

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-2,800.00

Save $-2,800.00

Nomad 3 Desktop CNC Mill: Professional-Grade Power in a Compact Package The Nomad 3 Desktop CNC Mill from Carbide 3D is the next evolution of prec...

View full details Save $-1,799.00

Save $-1,799.00

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-949.00

Save $-949.00

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full details

A CNC machine for wood is a computer-controlled cutting system that uses programmed tool paths to shape, carve, engrave, or mill wood automatically. Common types include cnc router machines for wood, cnc engraving machines for wood, and cnc milling machines for wood, all designed to produce precise, repeatable results.

The cost depends on size, power, and capabilities. A small cnc machine for wood may cost a few thousand dollars, while a large cnc machine for wood used in production environments can range significantly higher. Price is influenced by working area, spindle power, frame construction, and automation features.

Yes, CNC machines are widely used for woodworking. CNC machines for wood cutting, carving, and engraving handle materials like hardwoods, softwoods, MDF, plywood, and composites with consistent accuracy and clean finishes.

CNC is an investment, but it often reduces long-term costs by improving efficiency, minimizing material waste, and reducing labor time. For businesses, CNC routers for wood frequently pay for themselves through increased output and repeatable quality.

CNC and PLC serve different purposes. CNC systems are ideal for precision motion tasks like wood cutting and carving, while PLCs are better suited for automation control logic. For woodworking, a cnc machine for wood is the correct and more capable solution.

CNC machines for wood are generally energy-efficient relative to their output. Power usage depends on spindle size, runtime, and machine scale, but most cnc router machines for wood consume less electricity than many traditional industrial tools.

With proper maintenance, CNC machines can last 10–20 years or more. High-quality cnc routers for wood built with rigid frames and reliable components offer long service life, even in demanding production settings.

While building a CNC may seem cheaper upfront, buying a professionally manufactured cnc machine for wood usually provides better accuracy, reliability, safety, and support. For most users, purchasing a ready-made machine delivers greater long-term value.

CNC machines are used for cabinetry, furniture, signage, decorative panels, musical instruments, and custom woodworking. CNC machines for wood carving and engraving excel at intricate designs that are difficult to achieve by hand.

The right size depends on material dimensions and production volume. Small cnc machines for wood are ideal for hobbyists and compact shops, while large cnc machines for wood support full-sheet processing and higher throughput.

Shipping Insurance ($89)