Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full detailsOur CNC machines for steel cutting and engraving are built for makers, fabricators, and production shops that require true metal-grade rigidity and accuracy. From compact desktop CNC milling machines for steel to full-frame CNC metal cutting machines, these systems deliver clean cuts, tight tolerances, and consistent surface finishes across carbon steel, stainless steel, and tool steel.

Whether you’re machining mechanical parts, firearm components, jigs, brackets, or engraved metal plates, a CNC router for steel gives you digitally controlled depth, feed rate, and toolpath precision. These small CNC machines for steel transform raw stock into repeatable, production-ready parts with confidence and efficiency.

Save $0.00

Save $0.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-5,700.00

Save $-5,700.00

Shapeoko HDM CNC Router: Industrial-Grade Precision for Professionals and Makers Alike The Shapeoko HDM CNC Router represents the peak of precision...

View full details Save $0.00

Save $0.00

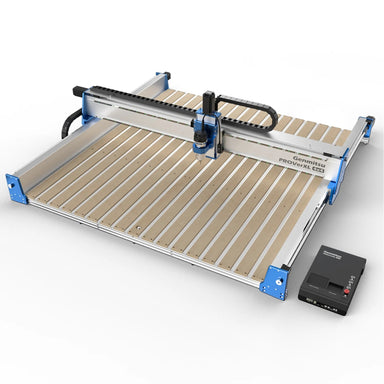

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-1,399.00

Save $-1,399.00

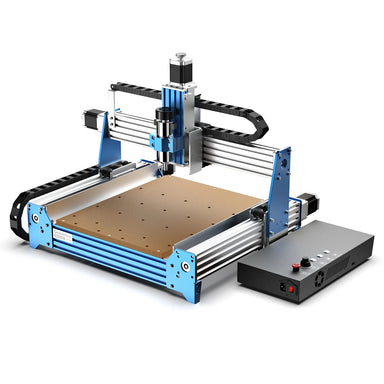

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $0.00

Save $0.00

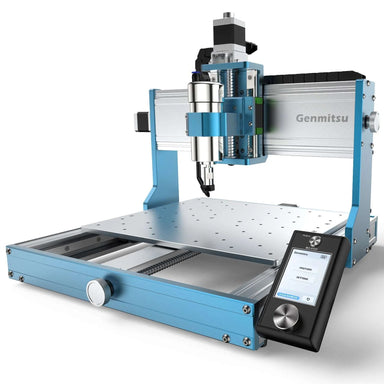

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-2,800.00

Save $-2,800.00

Nomad 3 Desktop CNC Mill: Professional-Grade Power in a Compact Package The Nomad 3 Desktop CNC Mill from Carbide 3D is the next evolution of prec...

View full details Save $-1,799.00

Save $-1,799.00

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-949.00

Save $-949.00

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full detailsYes — properly designed CNC machines can cut steel safely and accurately. A CNC machine for steel cutting uses rigid frames, ball screws, and metal-grade spindles to machine stainless, carbon, and tool steels with controlled feed rates and consistent tolerances.

CNC is very approachable — most beginners can learn basic machining in days, not years. Modern CNC software, guided toolpath generators, and pre-built cutting profiles make it easy to start producing real parts quickly, even on a desktop CNC machine for steel.

A CNC milling machine for steel is designed with higher rigidity, stronger spindles, and precision ball screws to handle metal cutting forces. Routers are better for soft materials, while mills provide accurate depth control and vibration-free machining for steel.

Yes — desktop CNC machines for steel are ideal for prototyping, education, and small-batch production. They are capable of cutting steel at slower feed rates while maintaining professional-grade accuracy.

Most small CNC machines for steel can machine ¼″–1″ steel stock, while industrial machines can handle significantly thicker material depending on tooling, spindle power, and cutting strategy.

Absolutely — a CNC machine for steel engraving can etch serial numbers, logos, text, and detailed patterns into hardened and stainless steels with permanent, high-contrast results.

Steel is machined using solid carbide end mills, coated drill bits, engraving cutters, and coolant systems to maintain tool life, surface finish, and cutting stability.

Yes — coolant dramatically improves surface finish, tool life, and accuracy while preventing heat-related warping and premature tool wear.

Shipping Insurance ($89)