Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full detailsCNC machines for foam cutting are designed to shape, carve, and contour foam materials with speed and accuracy. From a small cnc machine for foam in a workshop to a full-scale cnc router for foam, these machines are ideal for creating complex shapes, prototypes, and dimensional designs.

Whether you’re producing packaging inserts, signage, molds, or sculpted forms, a cnc router machine for foam delivers smooth finishes and repeatable results. This collection includes 3d foam cutting machines built to handle soft and rigid foams with precise depth control.

Save $0.00

Save $0.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-5,700.00

Save $-5,700.00

Shapeoko HDM CNC Router: Industrial-Grade Precision for Professionals and Makers Alike The Shapeoko HDM CNC Router represents the peak of precision...

View full details Save $0.00

Save $0.00

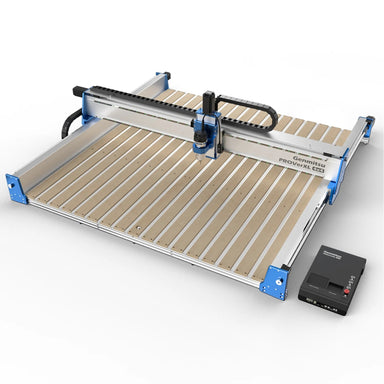

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-1,399.00

Save $-1,399.00

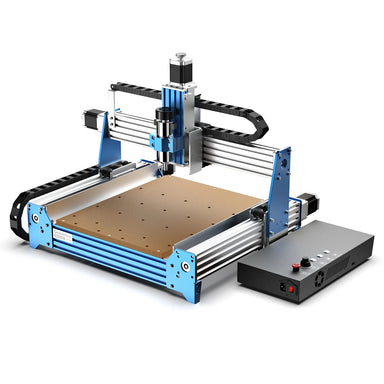

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $0.00

Save $0.00

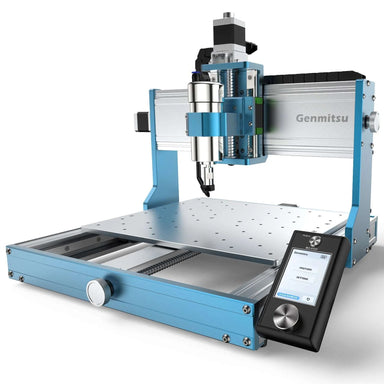

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-2,800.00

Save $-2,800.00

Nomad 3 Desktop CNC Mill: Professional-Grade Power in a Compact Package The Nomad 3 Desktop CNC Mill from Carbide 3D is the next evolution of prec...

View full details Save $-1,799.00

Save $-1,799.00

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-949.00

Save $-949.00

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full details

Yes, CNC machines are excellent for cutting foam. A cnc machine for foam cutting can shape soft and rigid foams accurately, making it ideal for packaging, signage, props, and industrial applications.

For CNC applications, single-flute or specialized foam-cutting bits work best. These tools minimize tearing and ensure smooth edges when used on a cnc router for foam.

Thick foam is best cut using multiple shallow passes or a long-reach cutting tool. CNC router machines for foam provide consistent depth control, making them ideal for cutting thick or layered foam materials.

Cold cutting with a CNC machine is generally more precise and versatile. Hot wire cutting works for simple shapes, but CNC cold cutting allows for complex 3D contours and detailed designs.

Softer foams like EPS, EVA, and polyurethane foam are among the easiest to cut. CNC machines handle these materials efficiently while maintaining clean edges and dimensional accuracy.

CNC machines can cut EPS, XPS, EVA, polyethylene, polyurethane, and rigid insulation foams. The type of foam determines tool selection and cutting strategy.

Yes, CNC machines are ideal for 3D foam cutting and sculpting. A 3d foam cutting machine allows for complex contours, layered designs, and smooth surface transitions.

A small cnc machine for foam is more than powerful enough for most foam applications. Foam requires minimal cutting force, making compact machines suitable for detailed and large-scale designs alike.

CNC foam cutting is widely used in packaging, signage, aerospace, automotive, construction, film and theater props, and product prototyping.

Foam cutting can create debris, but proper dust extraction and chip collection keeps the workspace clean and safe during CNC operation.

Shipping Insurance ($89)