Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full detailsATC CNC machines are built to maximize productivity by automatically switching tools during machining operations. A cnc machine atc setup reduces manual intervention, shortens cycle times, and delivers consistent results across complex jobs.

From cabinet production to industrial fabrication, an atc cnc router supports multi-tool workflows with speed and precision. This collection features automatic tool changer CNC machines designed for efficiency, accuracy, and continuous operation.

Save $0.00

Save $0.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-5,700.00

Save $-5,700.00

Shapeoko HDM CNC Router: Industrial-Grade Precision for Professionals and Makers Alike The Shapeoko HDM CNC Router represents the peak of precision...

View full details Save $0.00

Save $0.00

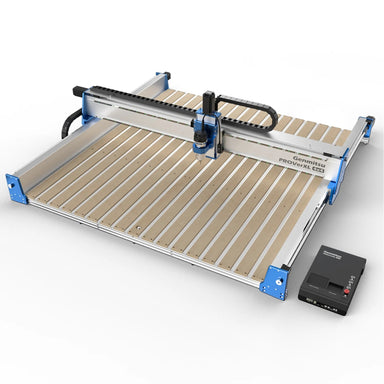

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-1,399.00

Save $-1,399.00

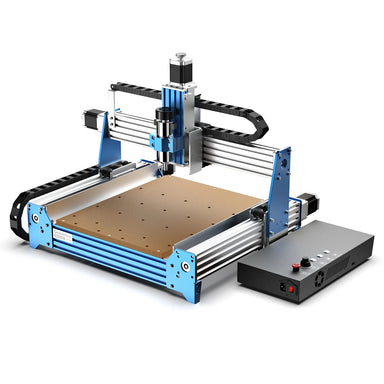

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $0.00

Save $0.00

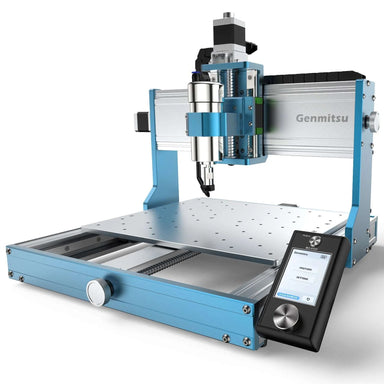

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-2,800.00

Save $-2,800.00

Nomad 3 Desktop CNC Mill: Professional-Grade Power in a Compact Package The Nomad 3 Desktop CNC Mill from Carbide 3D is the next evolution of prec...

View full details Save $-1,799.00

Save $-1,799.00

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-949.00

Save $-949.00

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full details

ATC stands for Automatic Tool Changer. In a CNC machine, ATC allows tools to be changed automatically during a job without stopping the machine or manual intervention.

The full form of ATC is Automatic Tool Changer, a system designed to improve efficiency and reduce downtime in CNC machining.

An ATC system works by storing multiple tools in a magazine or carousel. When a tool change is required, the machine automatically swaps the active tool with the next programmed tool.

An ATC spindle is a spindle designed to accept and release tools automatically. It works with the tool changer system to ensure fast, secure, and repeatable tool changes.

ATC CNC routers provide faster production, reduced labor, improved accuracy, and smoother workflows, especially for jobs that require multiple tools.

Tool capacity depends on the machine design. ATC CNC router machines may hold anywhere from a few tools to several dozen, depending on the magazine type.

For production environments, ATC CNC machines are highly valuable. They significantly reduce job time and operator involvement, making them ideal for scaling operations.

ATC machines use standard CNC programming with tool change commands, and modern CAM software makes setup straightforward.

ATC CNC machines are widely used in cabinet making, furniture production, signage, aerospace, and industrial manufacturing.

Yes. While ATC machines are advanced, modern interfaces and software make them accessible with proper training, even for users upgrading from manual tool change systems.

Shipping Insurance ($89)