Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full detailsCNC machines for small business help entrepreneurs produce high-quality products with speed, accuracy, and repeatability. Whether you’re launching a custom shop or scaling production, a cnc machine for small business offers the flexibility to cut, carve, and machine materials efficiently.

From a cnc router for small business workshops to a wood cnc machine for small business operations, these machines are designed to maximize output without requiring industrial-scale space or budgets. Explore solutions built to support growth, profitability, and long-term reliability.

Save $0.00

Save $0.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-5,700.00

Save $-5,700.00

Shapeoko HDM CNC Router: Industrial-Grade Precision for Professionals and Makers Alike The Shapeoko HDM CNC Router represents the peak of precision...

View full details Save $0.00

Save $0.00

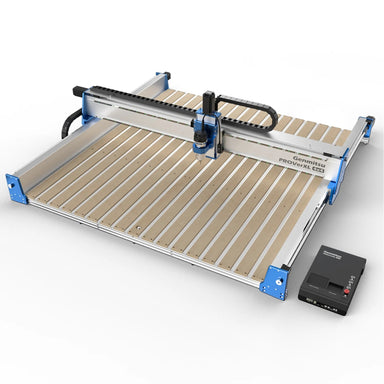

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-1,399.00

Save $-1,399.00

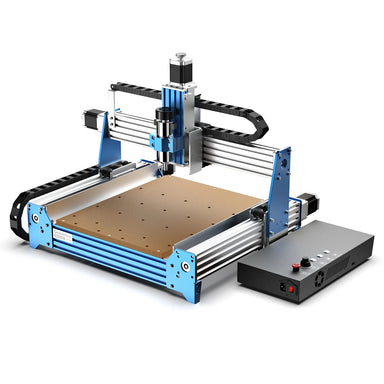

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $0.00

Save $0.00

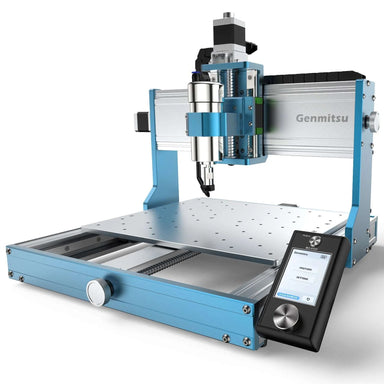

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-2,800.00

Save $-2,800.00

Nomad 3 Desktop CNC Mill: Professional-Grade Power in a Compact Package The Nomad 3 Desktop CNC Mill from Carbide 3D is the next evolution of prec...

View full details Save $-1,799.00

Save $-1,799.00

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-949.00

Save $-949.00

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full details

Yes, CNC can be highly profitable when paired with the right niche, materials, and workflow. CNC machines for small business allow owners to offer custom products, reduce labor costs, and scale production efficiently.

The right size depends on material dimensions, workspace, and production goals. Small businesses often start with compact machines and scale up as demand increases. A cnc machine for small business should balance capacity with available space.

Yes, a CNC business can be profitable due to low per-part costs and high repeatability. Many small businesses use CNC routers to create signs, furniture, décor, prototypes, and custom components with strong margins.

Common issues include tool wear, incorrect feeds and speeds, dust buildup, and software setup errors. These problems are typically easy to manage with proper maintenance, training, and material-specific settings.

CNC machines for small business can cut wood, plastics, acrylic, MDF, foam, and light metals, depending on machine design and tooling.

Many small businesses begin generating revenue within weeks or months, especially when serving local markets or offering custom, made-to-order products.

Routine CNC maintenance is straightforward and includes cleaning, lubrication, and tool replacement. Proper upkeep ensures long machine life and consistent results.

For many small businesses, owning a CNC router provides greater control, faster turnaround, and higher margins compared to outsourcing production work.

Shipping Insurance ($89)