Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full detailsCNC machines for guitar building give luthiers and makers the precision needed for consistent, high-quality instruments. From shaping bodies and necks to routing pickup cavities, a cnc router for guitar building delivers repeatable accuracy while preserving craftsmanship.

Whether you’re a custom builder or scaling production, a cnc guitar machine streamlines guitar making without sacrificing detail. This collection features CNC solutions designed specifically for guitar building, prototyping, and small-batch production.

Save $0.00

Save $0.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-5,700.00

Save $-5,700.00

Shapeoko HDM CNC Router: Industrial-Grade Precision for Professionals and Makers Alike The Shapeoko HDM CNC Router represents the peak of precision...

View full details Save $0.00

Save $0.00

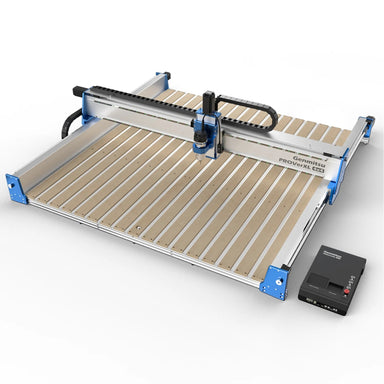

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-1,399.00

Save $-1,399.00

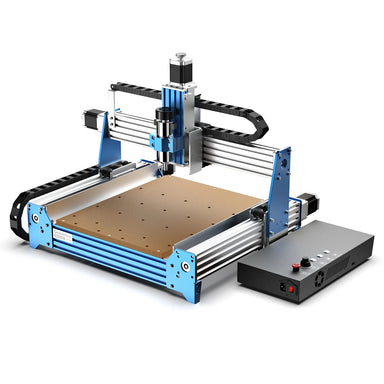

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $0.00

Save $0.00

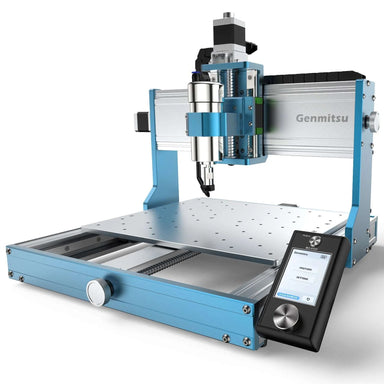

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-2,800.00

Save $-2,800.00

Nomad 3 Desktop CNC Mill: Professional-Grade Power in a Compact Package The Nomad 3 Desktop CNC Mill from Carbide 3D is the next evolution of prec...

View full details Save $-1,799.00

Save $-1,799.00

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-949.00

Save $-949.00

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full details

The cost varies based on size, rigidity, and precision. A cnc machine for guitar building can range from compact, affordable options for small shops to professional-grade guitar making CNC machines for production-level work.

Yes, CNC machines are widely used to produce guitar bodies, necks, and components. CNC for guitars ensures accurate shaping and symmetry while allowing builders to complete final sanding, assembly, and finishing by hand.

Many luthiers use a CNC router designed for woodworking, often referred to as a guitar CNC router. These machines offer the precision needed for neck profiles, fret slots, and cavity routing.

Most builders choose a CNC machine with a work area large enough for full guitar bodies and neck blanks. A mid-size cnc machine for guitars balances space efficiency with flexibility for different guitar styles.

Building a guitar can be more cost-effective for custom or boutique instruments, especially when using CNC for guitar building to reduce labor time and material waste.

CNC machining a guitar body typically takes one to several hours, depending on complexity, tool changes, and material type. CNC dramatically reduces shaping time compared to manual methods.

Yes, CNC machines provide extremely accurate and repeatable neck profiles, which is one of the main reasons guitar builders adopt CNC technology.

CNC guitar machines can work with tonewoods such as maple, mahogany, alder, ash, and basswood, as well as MDF and plastics for templates and jigs.

No. CNC enhances guitar making by handling precision work, while final shaping, fretwork, finishing, and setup remain hands-on processes.

Absolutely. Many small workshops use a cnc machine for guitar building to increase consistency, reduce production time, and expand design capabilities.

Shipping Insurance ($89)