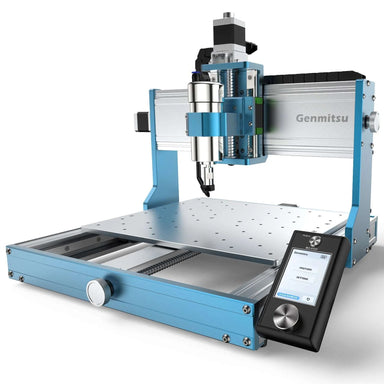

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full detailsCNC machines for acrylic deliver clean edges, smooth finishes, and precise detail for cutting and machining plastic materials. Whether you’re using a small cnc machine for acrylic in a home workshop or a full-scale cnc router for acrylic in production, these machines offer reliable control for clear and colored acrylic sheets.

From acrylic CNC signage and display work to detailed cnc machining acrylic for industrial and creative applications, this collection features machines designed for accuracy, repeatability, and material stability. Explore cnc router machines for acrylic cutting that support everything from prototyping to full-run manufacturing.

Save $0.00

Save $0.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-5,700.00

Save $-5,700.00

Shapeoko HDM CNC Router: Industrial-Grade Precision for Professionals and Makers Alike The Shapeoko HDM CNC Router represents the peak of precision...

View full details Save $0.00

Save $0.00

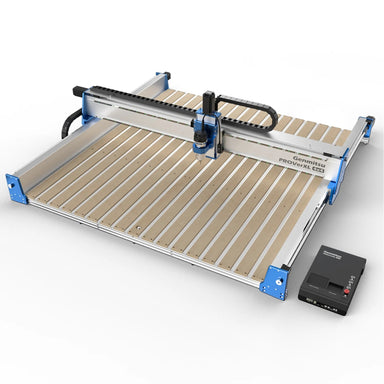

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-1,399.00

Save $-1,399.00

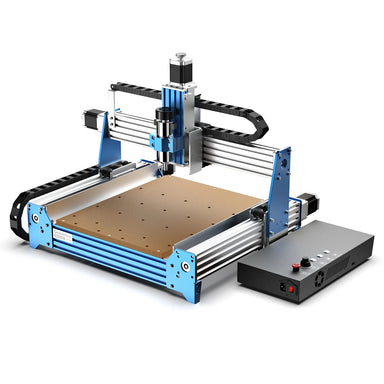

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $0.00

Save $0.00

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-2,800.00

Save $-2,800.00

Nomad 3 Desktop CNC Mill: Professional-Grade Power in a Compact Package The Nomad 3 Desktop CNC Mill from Carbide 3D is the next evolution of prec...

View full details Save $-1,799.00

Save $-1,799.00

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-949.00

Save $-949.00

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full details

Yes, CNC machines are highly effective for cutting acrylic. A cnc machine for acrylic cutting uses controlled spindle speeds and proper tooling to produce smooth edges without cracking or melting, making it ideal for signs, panels, and custom parts.

Pricing varies based on machine size, rigidity, and performance. A small cnc machine for acrylic or an acrylic cutting machine for home use typically costs less, while industrial cnc router machines for acrylic with larger work areas and higher precision cost more.

Both cast acrylic and extruded acrylic can be machined with CNC. Cast acrylic is often preferred for cnc machining acrylic because it produces cleaner chips and better edge quality, while extruded acrylic is more economical for simple cutting jobs.

CNC and laser machines serve different purposes. CNC routers for acrylic excel at thicker materials, pocketing, drilling, and 3D machining, while lasers are better for thin acrylic and polished edges. For versatility and material thickness, a cnc machine acrylic setup is often the better choice.

RPM depends on tool size, flute count, and feed rate, but acrylic is typically cut at higher spindle speeds with proper chip evacuation. Using the correct RPM helps prevent melting and ensures smooth, consistent cuts.

Absolutely. CNC machines are commonly used to cut acrylic for signage, displays, enclosures, and custom components. Even a wood CNC machine for acrylic can work effectively when paired with the right bits, speeds, and feeds.

Acrylic can melt if feeds and speeds are incorrect, but properly configured cnc routers for acrylic avoid this issue. Clean chip removal and sharp tooling are key to maintaining edge quality.

Yes, an acrylic cutting machine for home use is safe when operated correctly. Proper dust extraction, eye protection, and secure workholding help ensure safe and controlled operation.

CNC machines can cut thin sheets to thick acrylic panels, depending on spindle power and machine rigidity. Larger cnc router machines for acrylic handle thicker materials with greater stability and accuracy.

CNC machining acrylic is widely used in signage, retail displays, architecture, product design, prototyping, and manufacturing, where precision and repeatability are essential.

Shipping Insurance ($89)