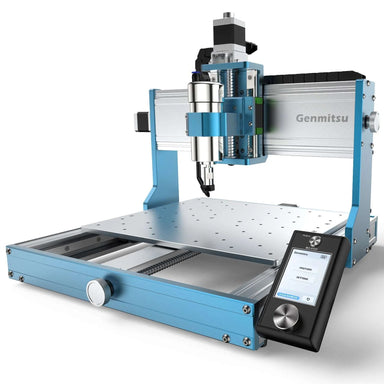

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full detailsHigh-precision CNC machines are engineered for applications where accuracy, consistency, and surface finish are critical. From detailed components to tight-tolerance parts, a high precision cnc machine delivers repeatable results across demanding materials and industries.

Whether you need a high precision cnc milling machine for metalwork or a high precision cnc router for fine detail cutting, these machines are built to minimize vibration and error. This collection features CNC systems designed for exacting standards and professional-grade performance.

Save $0.00

Save $0.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-5,700.00

Save $-5,700.00

Shapeoko HDM CNC Router: Industrial-Grade Precision for Professionals and Makers Alike The Shapeoko HDM CNC Router represents the peak of precision...

View full details Save $0.00

Save $0.00

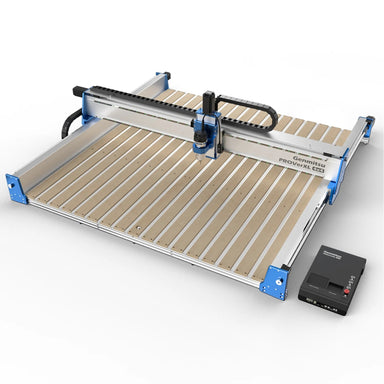

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-1,399.00

Save $-1,399.00

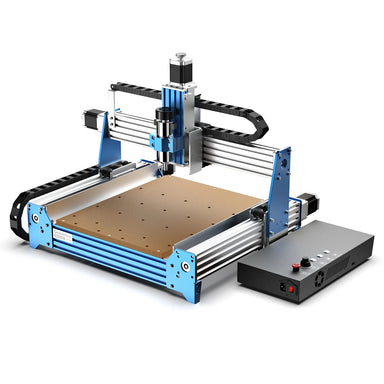

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $0.00

Save $0.00

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Sale

Sale

[NOTE: Shapeoko 5.1 Pro leg kits have a lead time of 17 days. If ordering the legs, they will all ship as one package once the legs are available.]...

View full details Save $-2,800.00

Save $-2,800.00

Nomad 3 Desktop CNC Mill: Professional-Grade Power in a Compact Package The Nomad 3 Desktop CNC Mill from Carbide 3D is the next evolution of prec...

View full details Save $-1,799.00

Save $-1,799.00

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-949.00

Save $-949.00

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full details

The most precise CNC machines are those built with rigid frames, high-quality linear guides, precision ball screws, and advanced motion control. High precision CNC milling machines and high precision lathe machines are typically used for the tightest tolerances.

Modern CNC machines can achieve tolerances within microns, depending on machine design, tooling, and environmental conditions. CNC high precision systems are capable of extremely consistent results across repeated production runs.

Precision is influenced by machine rigidity, spindle quality, motion components, software control, and calibration. Temperature control and vibration reduction also play a significant role in maintaining accuracy.

No. While often used for metal machining, high precision CNC routers are also used for plastics, composites, ceramics, and fine woodworking where detail and accuracy matter.

High-precision CNC machines are commonly used in aerospace, medical devices, electronics, automotive, tooling, and advanced manufacturing, where tolerances are critical.

For applications requiring tight tolerances, repeatability, and premium surface finish, a high-precision CNC machine is a valuable long-term investment that reduces rework and scrap.

They require consistent calibration, clean operating environments, and proper lubrication to maintain accuracy over time. Preventive maintenance is essential for long-term precision.

Yes. High-precision CNC machines are designed for continuous operation in professional environments, provided proper maintenance and environmental controls are in place.

High-precision CNC machines offer tighter tolerances, smoother motion, better surface finishes, and higher-quality components compared to standard machines.

Yes, though they are best suited for users who understand tooling, setup, and process control, as precision machines magnify both good and bad machining practices.

Shipping Insurance ($89)